UNIVERSITY OF BELGRADE

FACULTY OF MINING AND GEOLOGY

đušina 7, Belgrade, Republic of Serbia

TECHNICAL RESULT – m85

Software solution for coal quality control at the mine planning

phase

Softver za upravljanje kvalitetom

uglja u fazi planiranja eksploatacije uglja

Project

Name:

IMPROVEMENT OF LIGNITE OPENCAST MINING TECHNOLOGY IN

ORDER TO INCREASE ENERGY EFFICIENCY AND OCCUPATIONAL SAFETY

UNAPREĐENJE

TEHNOLOGIJE POVRŠINSKE EKSPLOATACIJE LIGNITA U CILJU POVEĆANJA ENERGETSKE

EFIKASNOSTI, SIGURNOSTI I ZAŠTITE NA RADU

TR 33039

November 2013

Type of technical solution |

M85 - Software

development |

|

Authors |

Kolonja B.,

Knežević D., Lilić N., Stanković R. Stevanović D.,

Kolonja Lj., Banković M., Tomašević A. |

|

Name of technical solution |

Software solution for

coal quality control at the mine

planning phase |

|

To whom is a technical solution intended |

Electric Power Industry of Serbia |

|

The user of the technical solution |

MB "Kolubara", OPM "Kostolac" |

|

The year

of development |

2012/2013 |

|

Verification

of results |

By reviewers:

|

|

The

technical solution accepted by |

Faculty of Mining and Geology University of Belgrade |

|

Application

of results |

Electric Power Industry of Serbia |

|

Vrsta tehničkog rešenja |

M85 – Razvoj

softvera |

|

Autori tehničkog rešenja |

Kolonja B.,

Knežević D., Lilić N., Stanković R. Stevanović D.,

Kolonja Lj., Banković M., Tomašević A. |

|

Naziv tehničkog rešenja |

Softver za upravljanje kvalitetom uglja u procesu

planiranja eksploatacije uglja |

|

Za koga je raneno tehničko rešenje |

Elektroprivreda Srbije |

|

Ko koristi tehničko rešenje |

PD RB Kolubara, TE-KO Kostolac |

|

Godina izrade tehničkog rešenja |

2012/2013 |

|

Verifikacija rezultata |

Recenzenti:

|

|

Ko je prihvatio tehničko rešenje |

Rudarsko-geološki

fakultet Univerzitet

u Beogradu |

|

Primena rezultata |

Elektroprivreda Srbije |

Software solution for coal quality control at the

mine

planning phase

1.

Technology field of the technical result

The technical result is a software solution for

coal quality control

at the mine

planning phase and

belongs to the field of Energy, Mining Industry

and Energy Efficiency.

2.

Technical problem - Coal quality control at the mine

planning phase

Mine

planning is based on reliable estimates of coal grades of future mining blocks.

Consequently, in order to develop any coal quality control strategy, the mine

should have the capability to predict both the quality and the variability of

the pertinent coal parameters with some degree of certainty. Coal quality

cannot be controlled without some information about possible qualities of

future mining blocks. The control of coal quality at the mine phase is usually

planned from in-situ coal parameters which are estimated from coal samples.

These samples are commonly used to generate maps of in-situ coal parameters.

With such maps, it is possible to know in advance the effect of mining from

different benches of the surface mine, i.e., whether or not the required

quantity and quality of coal can be met during the planning period. Mine planning

is divided into four categories: long-term, medium-term, short-term and

operational planning [10].

The primary objective of long-term mine

planning is to develop mining sequences which will define the economic limit of

the mine. Because planning is usually done with relatively scanty information,

an effective coal quality (coal grade) control is not practically possible. The

medium-term planning is concerned with a time span from one to about ten years.

It provides information necessary for forecasting future production and cost.

There is also practical limitation in controlling coal quality during this

planning, owing to limited information about grades. The short-term planning

contains all activities which are planned between one and twelve months period.

The short range plan defines resources and labor requirements, future

production and cost. More distinct information about the nature of

mineralization and equipment performance is required in short range than medium

range planning.

Operational planning is concerned with daily or weekly

requirements of the mine. Proper operational planning must conform to short

term mine plans as well as satisfying many practical details that are unique to

day to day operations. Grade control problems are usually incorporated in the

operational planning provided that the necessary detail information is known in

advance. The planning objective may vary between mines. However, the most

common planning objective is maximization of tonnage, while meeting the

requirements of physical and geological constraints, policies and mining

methods. The basic data required in any operational planning are grade(s) or

coal quality and capacity. Difficulties in optimum production schedule are

caused by variability of grade and inability to accurately predict grades of

smaller mining units. Therefore, detailed information on coal properties is

essential for reliable operational mine planning [11].

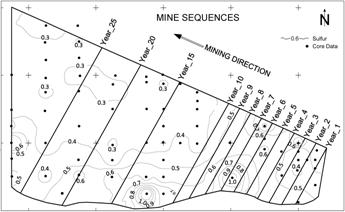

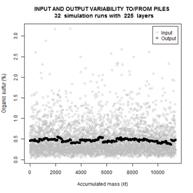

Generally two

types of grade variability exist in the coal chemical composition (Fig.1):

•

Long-term variability as measured

by trends of monthly or longer duration.

•

Operational variability is

generally measured by short period inter-train variability around the long-term

trend and is little affected by the long-term variability.

The

objectives of the operational mine planning model considered in this study are

two-fold. First, the coal quality requirements for a planning period must be

met, subject to some physical and geological constraints, policies and mining

methods. Secondly, the quantity requirements must ensure sufficient coal production.

Figure 1: Long-term and operational variability of SO2 grade

This model, in

general, is based on predicted information about the in-situ quality of the

coal deposit. Consequently, production scheduling for the purpose of

controlling coal quality, e.g., sulfur, have to be based on the predicted data

of the contemplated mining benches. The model uses zero-one programming formulation to

select potential working benches in surface coal mine on the basis of predicted

information. The standard optimization technique widely used in many

industrial applications is the linear and integer programming [12]. Models involve optimization of a quantity usually

referred to as the objective function subject to a set of constraints which

define the feasibility. In the operational mine scheduling, the decision to be

made is which working benches should be mined. A decision variable (1)

represents the i-th working bench and takes on a value of either zero (0) or

one (1).

(1)

(1)

With Xi denoting the i-th

working coal bench whose predicted sulfur and tonnage values for a planned

period, are sulfur (Si,%) and coal production (Ti, tons),

respectively, the objective function of an integer programming formulation of

reducing total sulfur content is expressed by equation (2) below.

, where n is the total number of coal working

benches. (2)

, where n is the total number of coal working

benches. (2)

The restriction with

regard to both quality and tonnage requirements are formulated in the following

way. First, run of mine composite sulfur (3) must not exceed maximum allowed, Smax (%), during a shift (or period).

(3)

(3)

Also, all working bucket wheel excavators (BWE's) must mine coal during a

period (or shift). This constraint (4) which guarantees a minimum production

during a period, assumes that during any period, the available BWE's do not

exceed the total number of potential working coal benches.

(4)

(4)

In practice, the surface coal mine is divided

into a number of mining phases, which are mined bench by bench, each bench

represented by a horisontal layer of blocks within the given mining phase and

having the same elevation. The mathematical formulation of the scheduling

procedure of mining blocs in terms of binary decision variables describing in

which period the particular block is extracted and what is its destination

(either directly to the power plant or to processing plant and stockyard) is

quite straightforward. But the hypothetical optimal block extraction sequence

may be completely impractical due to the technological requirements for the

mining equipment (BWE's) access and relocation.

3.

General research overview

According

to the International Energy Agency [1] forecast

for the next decades, coal will retain its important role in power generation

in Europe and worldwide. The availability of the worldwide coal resources and

their price stability are the main reasons for this trend. Coal is the most

important fuel in the generation of electricity, accounting for 65% of the

power produced in Serbia [2]. In the

past, because of the regulated business environment in which utilities

operated, coal was viewed as a necessary evil and was always treated as a

"pass through" cost. Although the quality of coal impacts boiler

operations and subsequent power produced and emissions, utilities had no

economic interest in monitoring or managing coal quality.

It is preferred that feeds the plants coals whose

properties, especially that of calorific value, conform to the power plant

design and whose sulfur content meets the sulfur emission requirement after

combustion. It is generally difficult to obtain coal of desired qualities from

one source because of the variable nature of coal properties. Homogenization of

coals from different working benches within the single mine or even more mines

are therefore becoming mandatory not only from an economic standpoint but also

from the necessity of meeting emission requirements.

At

the surface mine, coal is extracted from various active working benches and

then transported directly to the power plants or to stockyards. Because coal

properties can vary considerably, the quality of run of mine (ROM) coal

composite will depend on both the quality and quantity of coal mined from each

active bench. If it is desired to control the ROM coal quality, the rate of

coal production from each active bucket wheel excavator (BWE) should be

regulated. The effect of this approach is to blend the coal through the

sequence of mining. Such an approach requires a prior knowledge of the coal

quality of planned mining blocks.

Coal homogenization is one of mostly used options for

optimisation of sulfur emissions from desulfurazation power plants [2]. However, decisions about coal homogenization must

deal with uncertainty and variability in coal properties, and with the effect

of off-design coal characteristics on power plant performance and cost. According to Shih and Frey [3] sulfur and ash content and heating value are

considered as normally distributed random variables. The objectives of a model

to optimize operation of a plant must include minimizing: (i) the expected

(mean) costs of coal blending; and (ii) the variance of coal blending costs.

The cost objective function includes coal purchasing cost, ash disposal cost,

sulfur removal cost, and fuel switching costs. Chance constraints include

several risk measures, such as the probability of exceeding the sulfur emission

standard.

Homogenization piles are frequently used in order to

reduce variability and ensure coal stock. In this context, the most important

factors, in respect to pile building can be cited as the type of layer

disposition, number of layers and added mass. The last variable can

significantly reduce pile variability when a large material amount is

homogenized, and variability among the lots decreases [4, 5]. The deposition sequence of the material also is able

to affect grade predictability of each pile, requiring a more careful mining

advance forecast. Often, this scheduling is represented by a vector of grades

to coal blocks that will be mined along a given activity time, and

geostatistical techniques are used to predict them.

Some

previous studies involving blending and homogenization piles and geostatistical

simulations are described [6, 7]. US power stations have experienced reduction in SOx

emissions, by up to 20%, by homogenizing coal feeds to power plants [11].

Kriging technique is a very good estimator, but it is

not adequate to predict the uncertainty of a process. According to [9], on contrary to kriging, geostatistical simulation

methods aim to reproduce in situ variability,

and the spatial continuity of the input data set. Models used in this way, aim

to replicate the spatial structure of a data set as a whole rather than provide

reliable local estimates of an attribute at particular locations.

The stochastic simulated model honors values at the

sampled points and it reproduces the same dispersion characteristics of the

original data set (i.e. the mean, variance and covariance or variogram). It is

possible to address questions referring to the dispersion of the grades during

operational mine planning or stocking process, since the dispersion

characteristics of the original data are maintained.

4.

Description of the technical solution

4.1. Coal

homogenization at the stockyard phase

Homogenization is stocking the ROM coal in

layers, in their correct proportions, in the same stockpile, then reclaiming

across the full face. In any blending pile the attenuation on variability

depends on the equipment used and the way coal is stocked and reclaimed [6].

The main factors influencing

blending efficiency are the pile size or its mass and the number of layers used

to build pile. The aim in the homogenization process is to narrow down the

standard deviation of the normal distribution. A measure of the quality of the homogenizing process

is defined by the homogenizing efficiency (HE). In

simplified terms, and subject to certain statistical assumptions, the resultant

homogenizing effect is

calculated as the variability of the incoming coal on

pile (e.g. S %) and the variability of the outgoing coal from pile [13]:

![]() @ 0.5

@ 0.5 ![]() , where n is

number of layers. (5)

, where n is

number of layers. (5)

By

grouping exploitation mining blocks and forming a pile, the average grade of

this pile is closer to the planned mean if compared to the grades of each

individual block which comprise the pile. This phenomenon of variance reduction

is well known and it is referred to as the volume-variance relationship [4, 5].

Prior to designing the homogenization stockyard it is necessary to

know the sulfur content of coal that will form the pile. These grades come from

a geological block model mined according to a sequence determined by an optimal

mine scheduling. These block models however are obtained via classical

interpolation algorithms, such as ordinary kriging. In these situations, the

uncertainty associated with the interpolated value cannot be properly

incorporated [9]. As a

result of the so-called smoothing effect, the variance of the estimated values

is smaller than that of the original data. There are also limitations

associated with the use of the kriging variance as a measure of uncertainty [8].

The methodology suggested in this study quantifies the variability

of the homogenization pile by using multiple equally probable realizations

derived from a lognormally simulated sulfur distribution. Models used in this

way, aim to replicate the spatial structure of a data set as a whole rather

than provide reliable local estimates of an attribute at particular locations.

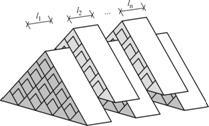

4.2. The stocking model

From

operational mine plan the coal benches mined are forming each windrow stockyard

pile. These multiple mining benches are an initial blending attempt as distinct

coals are combined to ensure sulfur regularity minimum.

Software

solution takes as input all needed design parameters, so very detailed analyses

are possible. First input parameter is number of layers in base, from which

software calculates total number of layers. There are n layers in the

base. One can observe that there is an n-1 layer in the next row, but

also that rhombus, and corner shaped layers are paired. So, in all non-base

rows of layers, there is

![]()

pairs of

square and corner shaped layers. Then total number of all base and non-base

rows is

![]() (6)

(6)

So,

the total number of layers is the square of number of layers in base. So, for

example, if input number is 10, then total number of layers in pile is 100.

The stockpile geometry is given with: length, width, height and

slope are also input parameters. The software solution give possibility to

define stockpile geometry (shape) with length, width, height and slope as input

parameters, that provides easy adjustment for other, different stockpile size

and shape. Another feature of interface is visualization of cross section for

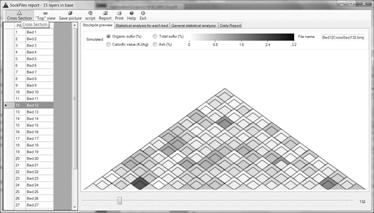

different stacking granularity, for selected pile and position within pile,

Figure 2. The shadings of layer’s cross sections in Figure 2 are corresponding

to the percentage of sulfur.

Figure 2. Software visualization of pile

cross section

4.3. The

reclaiming model

Developed reclaiming model determines the tonnage of

coal to be loaded from stockyard piles by reclaimer, so that the total sulfur

content of the reclaimed coal is minimised, while retaing the its heating value

within required range.

When a given pile is reclaimed at

the stockyard to feed the power plant, its real sulfur content is accessed via

averaging the sulfur contents from generated samples along time intervals. This

average sulfur content is the possible value to be used as real feeding values

for power plants.

Bed blending assumes that each reclaim slice (Fig. 3) includes

equal amounts of material from all layers of material stacked. This is good

approximation for some bed-blending systems, but it is not a good approximation

for most mineral stockpiling systems. Therefore, we describe prediction of the

performance of stockpiling systems for which reclaim slices include unequal

amounts of material from the layers of material stacked, Fig. 3.

Figure 3. Reclaiming slices from windrow pile

Quality

of the reclaimed material is calculated as the weighted average of pieces of

the layers that are taken from the bed. In this calculation, each piece’s

quality is weighted by its volume. More precisely, let ![]() be the average

grade of the material in layer

be the average

grade of the material in layer ![]() such that its

distance from the beginning of the layer is in the range

such that its

distance from the beginning of the layer is in the range ![]() where

where ![]() the cut depth of the reclaimed is. Now, the layers can

be described by the matrix

the cut depth of the reclaimed is. Now, the layers can

be described by the matrix

where ![]() is the number of

stocked layers,

is the number of

stocked layers, ![]() is the length of

the bed, and

is the length of

the bed, and ![]() . The volume of the material reclaimed from layer

. The volume of the material reclaimed from layer ![]() in cut

in cut ![]() is denoted by

is denoted by![]() . The average grade of material reclaimed in whole cut

. The average grade of material reclaimed in whole cut ![]() is then computed

by the formula

is then computed

by the formula

. (7)

. (7)

When necessary, calculation of volumes includes Monte

Carlo integration for calculation of intersection area of arbitrary polygons

when the polygons are too complex. We describe the Monte Carlo integration

method we used. Let ![]() be a function,

and

be a function,

and ![]() the definite

integral of that function

the definite

integral of that function

(8)

(8)

on the

region of integration

![]() . (9)

. (9)

Monte

Carlo approximation of this definite integral is calculated using

![]() (10)

(10)

where ![]() is the volume of

the integration region, and

is the volume of

the integration region, and ![]() are the points

in the random sample taken from the integration region. The value

are the points

in the random sample taken from the integration region. The value ![]() converges to

true value

converges to

true value ![]() as

as ![]() goes to

infinity. The variance of this estimate is calculated as

goes to

infinity. The variance of this estimate is calculated as

![]() (11)

(11)

Since

the variation of an integral able function is bounded, the variance of the

estimate decreases as ![]()

Now, let ![]() be the

characteristic function of the polygon

be the

characteristic function of the polygon![]() . For each point, this function gives value 1 if that

point is in the polygon and value 0 if the point is out of the polygon. This

function can be calculated by taking an arbitrary ray (half-line) from the

point that intersects the sides of the polygon. If the number of intersections

is even, then the value of the function is 0, and if it is odd, the value of

the function is 1. By plugging this function in the general formula for Monte

Carlo integration, one can approximate the area of the polygon. In order to calculate

the intersection of the polygons

. For each point, this function gives value 1 if that

point is in the polygon and value 0 if the point is out of the polygon. This

function can be calculated by taking an arbitrary ray (half-line) from the

point that intersects the sides of the polygon. If the number of intersections

is even, then the value of the function is 0, and if it is odd, the value of

the function is 1. By plugging this function in the general formula for Monte

Carlo integration, one can approximate the area of the polygon. In order to calculate

the intersection of the polygons![]() , one should use the characteristic function of the

intersection which is the product of characteristic functions of polygons,

namely,

, one should use the characteristic function of the

intersection which is the product of characteristic functions of polygons,

namely, ![]() Nevertheless, in

often, the volume can be calculated exactly – without approximation.

Nevertheless, in

often, the volume can be calculated exactly – without approximation.

4.4.

Simulation methodology of coal quality control

The

primary objective of the simulation is to determine a sequence of mining tasks

to deliver the required coal quality and quantity to the power plants in the

short-to-medium term.

Simulation algorithms currently used in mining is more

appropriate than ordinary kriging to deal with matters related to data

variability. Mine production plans, scheduling, and blending strategies require

knowledge of the dispersion of relevant geological attributes [11, 14]. Fluctuations in mining engineering and geochemical

attributes of interest are also relevant for mine design and production

scheduling. For example, mapping the probability of grades exceeding a limiting

threshold within different areas of a deposit can warn of possible fluctuations

in the grades, with direct implications on the scheduled mining plan.

Stochastic simulation model is used to generate multiple,

equally probable scenarios of the phenomenon; each scenario reproduces the

value of the sampled data, their spatial continuity, represented by lognormal

model, and the histogram of the distribution, replicating the natural

variability of the sulfur. These scenarios provide a set of possible values for

each mining block, which form a homogenization pile. So, we generate many

values for the average of blending piles studied as there are various possible

scenarios generated by the simulation algorithm used.

Generation of dataset

for this case study was performed in statistical package Rsim [15, 16], with rlnorm function

which can generate random numbers whose distribution is lognormal, with

arguments: the number of random numbers, the mean and standard deviation. The

following code was used:

ss_mean=0.465; ss_stdev=0.351; ss_meanlog

=![]()

ss_sdlog =  ; y = rlnorm(1, ss_meanlog, ss_sdlog)

; y = rlnorm(1, ss_meanlog, ss_sdlog)

The steps involved in the study can be

summarized as:

1.

Build a consistent geological

database using drill holes and use this data to develop MinexTM coal

quality seem models to map the variability associated with the in situ

qualities. The method used to estimate block sulfur

content for operating mining plan is gridding by inverse distance squared. Generation of multiple equally probable models via Rsim.

2.

After its

construction, a mini block model is used for mining planning and scheduling. For

a given mining schedule and multiple simulated quality models, compose the

average content values for each pile system considering the number of blocks

forming each chosen stockpile and their respective qualities. Each generated pile is based on a scheduled sequence

of blocks forming the pile.

3.

Plot the

standard deviation from stockyard pile qualities in relation to planned average

for various pile sizes (masses). Check the size of the pile, which leads to an

acceptable range of content variation. Repeat (2) and (3) for each of several simulated models

of sulfur contents to map the influence of in situ qualities uncertainty on the

interpile quality fluctuation.

5.

Case study

The case study uses data from a coal deposit

located in Kolubara surface mine, Figure 4. The operating mining plan uses for

grade estimation the original geological dataset. The local geology of mine

includes 3 coal seams interbedded with waste material such as siltstones,

sandstones, shales, and other sedimentary rocks. Available samples include 1118

heating values and 632 sulfur values for analysis distributed in the coal seams

mentioned above. The samples considered for this study were separated by coal

seams. Samples were collected and analyzed at different length or support as

each coal seam has thickness variations from point to point.

The

Kolubara surface mine used for simulation is bounded by a rectangle, and mine

sequencing is developed using the coal within the rectangle (Figure 4). The box cut is a planned start at the northern

extreme of the area due to several technical operational reasons including an

adequate location for the topsoil provisional deposit from the first cut. The

area to be mined over the life of the mine was divided into 28 strips, 200 m

wide. The deposit used to illustrate the

methodology has 3 mineable coal seams, each with its own coal quality and own

average thickness. To compose the sulfur grade value for a mining blocks, it is

necessary to combine multiple sulfur grade values from each different coal seam

and multiple working benches.

Figure 4.

Field to

be mined and the strip sequence by years

Analises

has shown that in Kolubara surface coal mine some parts of deposit with high

content of sulfur, over 2% (fig. 7). Adjusted on share of 95 percentiles

content of sulfur is over 1%, althought

content in the most of parts of the deposit is under 0.4%. The space

distribution of sulfur required the homogenization of coal according to sulfur

as a leading parametre. Slave parameter

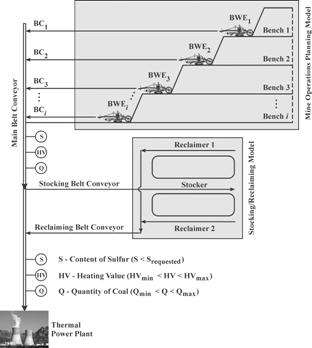

for homogenization is coal heating value. The integral

model for coal quality control is developed and consists of three sub-models:

operational mine scheduling model, stocking model and reclaiming model, fig 5.

Figure 5. Technological scheme of coal

homogenization in Kolubara surface mine

According simulated daily or shift mine plan each BWE has working

bench position and production parameters. Mass and quality control will be done

by on-line devices and weightmeters on main belt conveyor. If coal quality has

required values coal is transported directly to thermal power plant, if not

coal is transported on stockyard. Stacking and reclaiming will be controled by

its models.

To proceed with the pile emulator, a mining sequence associated to

the mine plan is required. Mean of sulfur content at each stockyard pile

directly depends on the coal block extraction schedule. This sequence is

determined by a planned mine advance. Before starting the stocking and the

analysis on the variability reduction with the increase of the number of

stockyard pile layers, it is necessary to understand all variability sources

influencing the pile homogenization system of the case study, namely:

-

variability of the sulfur grades

from each coal seam and bench11, bench12, … benchij.

-

variability of the sulfur grades,

which feed the stockyard (pile combining coal from several mining benches or

mines)

-

variability

among grades in homogenization piles (variability depending on number of

layers).

In this study we use a pile of 350.000 t

equivalent to new designed stockyard at the mine corresponding to 84 mining

blocks from the model. Piles were designed as 48 m wide and same length according

to the variable number of layers. To illustrate the procedure, the blocks

selected corresponded to the first year of production with a total of 4895

blocks. Each block has a grade obtained by Rsim, which, of course, differs

among them and is different from the global mean calculated for the first year.

By grouping various blocks and forming a pile, the average grade of this pile

is closer to the global annual mean when compared to the grades of each

individual block which comprise the pile, Figure 6.

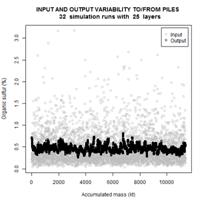

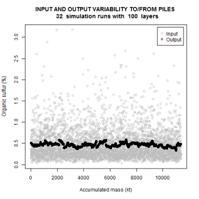

In this case study, we

analyzed the performance of the homogenization method for various blending bed

sizes. As illustration we present the variability of input and output data for

the cases of 25, 100 and 169 layers in each bed. Gray circles represent the

input data, horizontal axis corresponding to the cumulative mass of the coal

stacked up until the moment, and vertical axis corresponding to the percentage

of organic sulfur. Black circles represent the percentage of organic sulfur

after the homogenization. One can notice that the output consists of several

segments with rather small intersegment variation. Each segment corresponds to

one reclaiming cycle. The mean values of segments vary inevitably as the trend

changes in the input data.

Figure 6. Simulation results for

input/output variability of sulfur on pile

This explains why the grades in the reclaimed

coal from the piles led to a variance reduction in the grades feeding the power

plants as compared to the grade variability that would be obtained from a

mining block by block scheme feeding the power plant. A few other aspects

controlling the variance of the average grades among stockpiles are:

-

the larger the size of stockpile the smaller will be the variance

of the average grade of each pile around the planned mean grade,

-

as a consequence of the stockpile

size an extremely large pile hypothetically perfectly homogenized formed by all

blocks mined during planned period would lead to a zero variance around the

mean grade of this period (in theory).

However, the larger the pile

the better will be the homogenizing process; and from an operational point of

wiew the problems tend to grow in difficultly as the size of the stockyard

equipment involved increases. The adequate pile size is the minimum size which

will deliver coal to the plant with grades varying within a pre-determined and

acceptable grade interval.

Given all information necessary from operational mine planning and

scheduling to the stockyard simulation model, i.e. simulated block values and

mining sequence, the average sulfur values of the homogenization piles can be

obtained. The variability among piles was determined for variable number of

layers in the same pile size. It was taken into consideration that the mass of

each mined coal block is equivalent to BWE capacity on each coal seam.

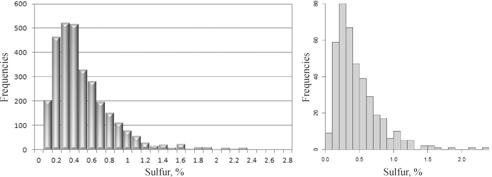

Figure 7.

shows that the simulated model adequately reproduced the histogram of the

declustered original data. Left part of the figure is plotted the histogram of

the original samples and in the right part the generated histogram by the

algorithm of sequential lognormal simulation for one geological domain studied.

Figure 7. Histograms for sulfur original data (left) and (d) to

simulated values of sulfur (right)

Given the validated simulated block model and the planned

mining sequence, it is possible to calculate a set of equally probable values

for the sulfur average that each blending pile can take. A pile is formed by a

set of blocks from different mine faces from multiple benches. The scenarios generated

by sequential Gaussian simulation would provide a group of possible values to

the blocks that form a homogenization pile. Consequently, the average organic

sulfur content calculated for each pile can assume as many values as simulated

scenarios.

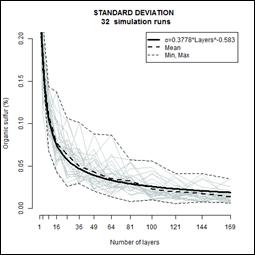

Figure 8. Average standard

deviation for variable pile sizes

The

algorithm developed considers the number of layers in piles and the

contribution that each seam from each block adds to the total mass of the pile.

When the number of layers and mass (size) of the pile is reached the algorithm

stops, takes the weighted average of the qualities from the blocks included in

this specific pile, and starts building the next pile.

Average

standard deviations for the sulfur from various pile sizes is given in Figure

8. The Figure illustrates the results

obtained for the intrapile standard deviation for each number of layers tested.

Note, the curves were plotted for all simulation runs constructing piles of

350.000 t and repeated 32 times (one for each simulated number of layers). It

is noticed that after 100 layers the standard deviation stabilizes. The curves

with the fitted (thick), minimum, average and maximum (dashed) standard

deviations versus the number of layers were highlighted. Horizontal axis refers

to the number of layers. Vertical axis refers to the standard deviation. An

exponential curve was fitted to these experimental points. The model derived

for the standard deviation of organic sulfur versus number of layers is shown.

6.

Conclusion

This technical solution reviewed

homogenization methods used in stockyards and proposed a methodology to

generate equally probable models mapping sulfur content within a coal deposit

in Kolubara surface mine. These models allow assessing the uncertainty

associated with the grade content in the ROM coal supplied to the power plant.

As the size (mass) of the pile increased, the quality fluctuations reduced

allowing the decision maker the choice of selecting a proper pile size to meet

an acceptable level of variability. The optimal size must be defined taking

into account capital and operational costs. The key message of stemming from the results in this

paper is that the simulation model provides a useful decision support tool to

compare operational mine scheduling and stockyard piles policies for controlling

coal quality. According to the model, it is possible to

reduce the variability of the grades exponentially as the mass of the pile

increases.

REFERENCES:

[1]

***, International energy outlook 2011, US Energy Information administration,

2011.

[2]

Ignjatović D., Knežević D., Kolonja B., Lilić N., Stanković

R.: Upravljanje kvalitetom uglja

("Coal quality management"), University of Belgrade, Faculty

of mining and geology, Belgrade, 2007.

[3]

Shih, J.S. and Frey, H.C. Coal blending optimization under uncertainty. Proceedings of the Tenth Annual

International Pittsburgh Coal Conference, Pittsburgh, Pennsylvania, 1993, pp.

1110–1115.

[4]

David, M., Developments in Geomathematics 2: Geostatistical ore reserve

estimation, First Edition.: Elsevier , Amsterdam 1977.

[5]

Parker, H. The Volume Variance Relationship: A Useful Tool for Mine Planning. Engineering and Mining Journal, vol. 180

(1979), pp.106–123.

[6]

Schofield, C.G., Homogenisation/Blending Systems Design and Control for

Minerals Processing, TransTech Publications, Claustehall 1980.

[7]

***, A review of the state-of-the-art in coal blending for power generation,

Final Report - Project 3.16., CRC, 2001,

[8]

Isaaks, E.H. and Srivastava, R.M., Applied Geostatistics, Oxford University

Press, New York 1989.

[9] Costa, J. F.C. L., Marques, D., Pilger,

G.G., Koppe, J. C. , Ribeiro, D.T., Batiston, E.L. and Costa, M.S.A.,

Incorporating in situ grade variability into blending piles design using

geostistical simulation, Proceedings

of the 3rd World Conf. on Sampling and

Blending, Porto Alegre. vol. 1, 2007. pp. 378–390.

[10]

Gershon. M. E., Mine Scheduling Optimization with Mixed Integer Programming,

AlME Fall Meeting, Honolulu, Preprint No. 82- 324, 1982.

[11]

Kim, Y. C., Knudsen, H. P. and Baafi, E, Y., Development of Emission Control

Strategies Using Conditionally Simulated Coal Deposits, University of Arizona,

Tucson, Proprietary report prepared for the Homer City Owners, Homer City, Pa.

15478, 1981.

[12]

Padberg, M W, Linear optimization and extensions, Springer, NY, 1995.

[13]

De Wet N., Homogenizing/Blending in South Africa - An update, Bulk solids

handling, Issue no.1, 1994.

[14]

Bivand, R., Pebesma, E., Rubio, V., Applied Spatial Data Analysis with R. Use R

Series, Springer, Heidelberg, 2008.

[15]

Murphy, T.D., Brown, K.E., Combining geostatistics and simulation to predict

sulphur at a central Illinois coal mine, Mining

Engineering (1993), 45, 284–287.

[16]

Rossiter, D. G., Introduction to the R Project for Statistical Computing for

use at ITC, 3rd Edition. International

Institute for 15 Geo-information Science & Earth Observation (ITC),

Enschede, Netherlands, 2009.